BHQ26 uchungechunge sandbast ikhabethe by manual

1.Iyini i-sand blast cabinet

Abanye abantu baphinde babize imishini yokuqhumisa isihlabathi, ithangi lokuqhumisa isihlabathi, i-sand blaster ephathekayo, imishini yokuqhumisa isihlabathi nokunye.Amagama ahlukene, kodwa anencazelo efanayo.Ingasebenza ngokuhlukana, kodwa ezimweni eziningi isebenza ngegumbi lokudubula.

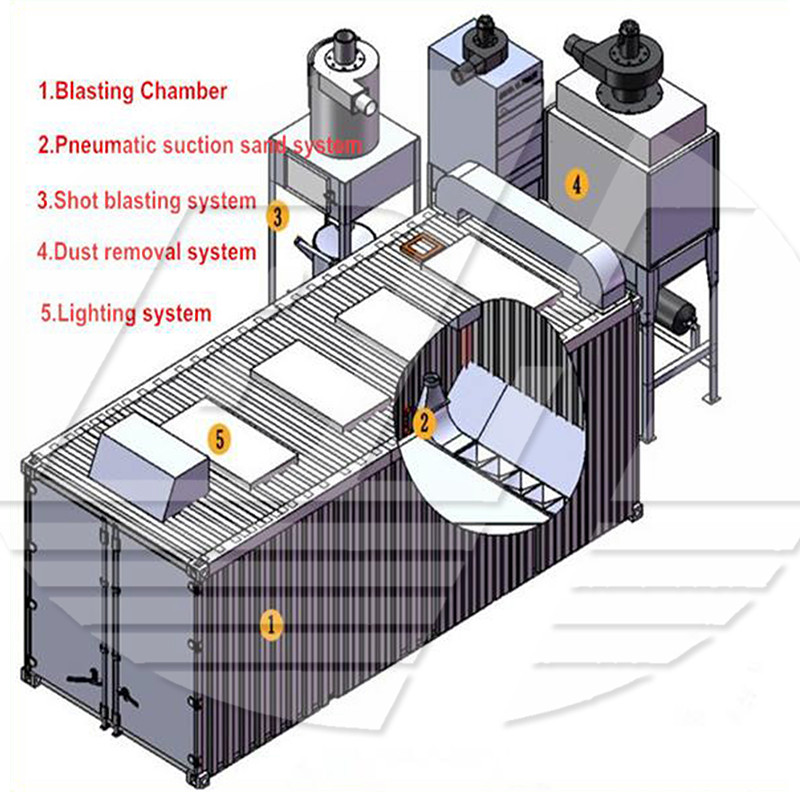

Ukwakhiwa kwekhabhinethi yokuqhuma kwesihlabathi ——

Ngokuvamile, izingxenye zimi kanje:

1).ithangi lokuqhuma isihlabathi:

Ugqinsi lwepuleti lensimbi elisetshenziselwa amavolumu ahlukene wethangi kanye nomsuka womshini we-sandblasting wehlukile.Uma ivolumu iba nkulu, i-steel plate iba mkhulu.Lokhu ikakhulukazi kunqunywa imboni yemikhumbi yokucindezela ngokuvumelana nesimo sangempela.

Kunezinhlobo ezimbili ze-valve yesihlabathi kanye ne-sand valve: i-manual noma i-pneumatic.Ngesandla, kuyadingeka ukuvula ngesandla i-valve yesihlabathi, futhi igesi ivulwa ngokuzenzakalelayo yigesi.

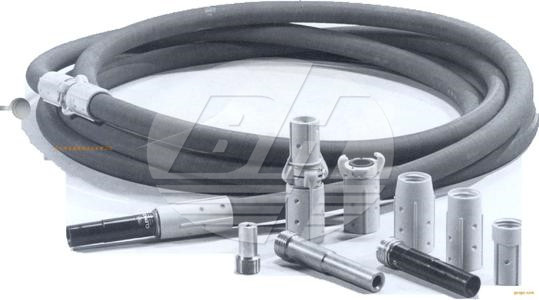

2).Ipayipi lokuqhunyiswa kwesihlabathi (okujwayelekile ngu-10m/20m)

3).I-valve yokuphepha

Ingcindezi yokusebenzisa ithangi le-sandblasting ngokuvamile i-8KG.Indima yevalvu yokuphepha Uma umfutho wegesi udlula u-8KG, uzozicisha ngokuzenzakalelayo.Ukuze uvikele ithangi le-sandblasting

I-4) . Isibhamu se-Sandblasting: Ngokusho kwempahla, ingahlukaniswa nge-boron carbide, i-alloy steel, i-tungsten carbide, insimbi nokunye.

Okuhlala isikhathi eside kakhulu i-boron carbide, futhi impilo yesevisi ngokuvamile ingamahora angu-500-700.

Okwesibili, impilo yesevisi ye-tungsten carbide ne-alloy steel ngokuvamile amahora angu-300-400,

I-ayoni ingasetshenziswa amahora angu-10 kuphela, bambalwa abantu abayisebenzisile.

Isistimu yokulawula ye-elekthronikhi nezinye izingxenye.

2.Isimiso sokusebenza se-sandblaster ephathekayo

Isimiso sokusebenza somshini wokuqhumisa isihlabathi sihlukile kumshini wokudubula oqhumayo.Umshini wokudubula usebenzisa amandla aphakathi nendawo ukwenza ukudubula.Umshini wokuqhumisa isihlabathi unikwa amandla wumoya ocindezelwe bese ufafaza ama-abrasives (kokubili isihlabathi esinensimbi nesingeyona insimbi) phezu kwendawo yokusebenza.Ngenxa yomthelela wengcindezi, i-abrasive ethangini lesihlabathi idlula ku-valve yesihlabathi kanye neshubhu yokuqhuma ukuya kusibhamu sesifutho, futhi i-abrasive ikhishwa ngesivinini esikhulu, esishintsha izici zemishini yendawo yangaphandle yendawo yokusebenza.Ngenxa yomthelela kanye nomphumela wokusika we-abrasive ebusweni bomsebenzi , Ukuze uthole izinga elithile lokuhlanzeka kanye nama-roughness ahlukene ebusweni bomsebenzi, thuthukisa izakhiwo zemishini yendawo yokusebenza, ngakho-ke uthuthukise ukumelana nokukhathala kwendawo yokusebenza, ukwandisa ukunamathela phakathi kwayo kanye ne-coating, futhi unwebe i-coating Ukuqina kwefilimu nakho kuhambisana nokulingana nokuhlobisa kwe-coating, ukususa ukungcola, umsindo kanye nezingqimba ze-oxide ebusweni, kuyilapho kuqhuma ubuso be-medium, kubangela ingcindezi eyinsalela endaweni engaphansi kanye nokwenza ngcono ubulukhuni bendawo engaphansi.

3.Ukucaciswa okuyinhloko kwe-sand blaster ephathekayo

4. Ukulahlekelwa amandla kwe-shot blast tank

1).Ukumiswa komthombo womoya womshini we-sandblasting ngokuvamile ngu-6m³/min (ukusetshenziswa komoya kwesibhamu esisodwa sokufuthwa, uma kungu-N, ukulungiselelwa komthombo womoya odingekayo ngu-N*6m³/min.

| Uhlobo Lwento | Q0250 | Q0250A-Ⅱ | Q0250A-Ⅱ-LX | ||

| Umthamo we-tank (m3) | 0.5 | 0.7 | 0.82 | ||

| Umfutho womoya (Mpa) | 0.5-0.6 | 0.5-0.6 | 0.5-0.6 | ||

| Umthamo okhishiwe (umthamo=φ10)(kg/h) | 1800-2280 | 1 isibhamu | 1800-2280 | 1 isibhamu | 1800-2280 |

| 2 izibhamu | 3600-4560 | 2 izibhamu | 3600-4560 | ||

| Ukusetshenziswa komoya (m3/min) | 6.1 | 1 isibhamu | 6.0 | 1 isibhamu | 6.0 |

| 2 izibhamu | 12.0 | 2 izibhamu | 12.0 | ||

| Ubude bepayipi eliqhumayo (mm) | 7000 | 7000 (2pcs) | 7000 (2pcs) | ||

| Indlela yokulawula | Isilawuli kude | Isilawuli kude | Isilawuli kude | ||

| Ubukhulu (mm) | 1036*812*1860 | 1120*900*1890 | 1086*812*2060 | ||

| Isisindo (kg) | 396 | 500 | 690 | ||

2).Umfutho womoya odingwa umshini we-sandblasting ngu-0.5-0.6mpa (uma ukucindezela kuphansi kakhulu, i-sandblasting izoba buthakathaka futhi umphumela wokuhlanza uzothinteka).

3).Inani le-sandblasting / shotblasting ngehora lomshini we-sandblasting ngu-1800-2100 kg.

4).Ububanzi besicelo se-sandblasting

a.Ukwelashwa kwangaphambili: zonke izindlela zokwelapha eziqhumayo ngaphambi kokuba zimbozwe, ezifana ne-electroplating, ukudweba, ukufafaza, njll., indawo engaphezulu ihlanzekile ngokuphelele, futhi ngesikhathi esifanayo ithuthukisa kakhulu ukunamathela nokumelana nokubola kwesendlalelo sesembozo.

b.Ukwelashwa kwangaphambili ngaphambi kokuhlanza ubuso bezingxenye: ukwehliswa, izinsalela nokungcola kwezingxenye zensimbi ezifana ne-castings, izingxenye zokunyathela, izingxenye ze-welding, izingxenye zokushisa ukushisa;ukuhlanza ubuso bemikhiqizo engeyona eyensimbi, ukususwa kwamabala amnyama ebusweni bezikhala ze-ceramic kanye nokunciphisa Iphethini kapende, njll.

c.Ukulungiswa kabusha kwezingxenye ezindala: ukulungiswa nokuhlanza zonke izingxenye ezihambayo ezifana nezimoto, izithuthuthu, imishini ye-electromechanical, njll. Ngesikhathi esifanayo susa ukucindezeleka kokukhathala futhi wandise impilo yesevisi.

d.Ukuqeda ukucubungula ebusweni bomsebenzi: yonke imikhiqizo yensimbi nemikhiqizo engeyona eyensimbi (ipulasitiki, ikristalu, ingilazi, njll.) imikhondo yangaphezulu iyasuswa, futhi ukwelashwa kwe-argon fog surface kwenza umkhiqizo uthuthuke.

e.Ukwelashwa kwesikhunta: Ukwelashwa kwe-Argon ukukhanya kwenkungu ebusweni besikhunta, ukukhiqizwa kwesithombe, nokuhlanza isikhunta, hhayi ukulimaza isikhunta, ukuqinisekisa ukunemba kwesikhunta.

f.Ukwelashwa kwe-Burr: Izingxenye zomshini zisuswa ngama-burrs amancane, futhi izingxenye zepulasitiki zezingxenye zomjovo ziyasuswa.

g.Ukuphinda kusetshenzwe kabusha kwemikhiqizo engathandeki: ukususwa kwengubo yomkhiqizo engathandeki, ukususwa kombala ongathandeki ebusweni nokususwa kokuphrinta.

h.Ukuqinisa: khulisa ubulukhuni bobuso bezingxenye zensimbi futhi uqede ingcindezi, njengokwelashwa okungaphezulu kwama-blade endiza, iziphethu, amathuluzi omshini nezikhali.

i.I-Etching kanye ne-anti-skid processing: amaphethini e-etching, umbhalo kanye nokwelashwa okulwa nokushushuluza ebusweni bemikhiqizo yensimbi nemikhiqizo engeyona eyensimbi, efana nale: imabula, izibambo ezilwa nokushushuluza, izigxivizo, ukubhalwa kwe-stele lettering, njll.

j.Ukwelashwa kwezingubo zedenim: Impahla yedenim i-matte, imhlophe kanye ne-whisker effect izuziwe.

5.Izinzuzo zekhabhinethi ye-sandblast:

1).Izingxenye zensimbi zomshini we-sandblasting ngokuyisisekelo azilimazi, futhi ukunemba kobukhulu ngeke kushintshe;

2).Ingaphezulu lengxenye alingcolisiwe, futhi i-abrasive ngeke isabele ngamakhemikhali nezinto zengxenye;

3).Umshini we-sandblasting ungakwazi kalula ukusingatha izingxenye ezingafinyeleleki ezifana nama-grooves nama-concaves, futhi ubukhulu obuhlukahlukene be-abrasives bungakhethwa ukusetshenziswa;

4).Izindleko zokucubungula ziyancipha kakhulu, ikakhulukazi ziboniswa ekuthuthukisweni kokusebenza kahle komshini we-sandblasting, ongahlangabezana nezidingo ezihlukahlukene zokuqeda ubuso;

5).Ukusetshenziswa kwamandla okuphansi kanye nezindleko eziphansi;

6).Umshini we-sandblasting awungcolisi imvelo, uqeda izindleko zokwelashwa kwemvelo;