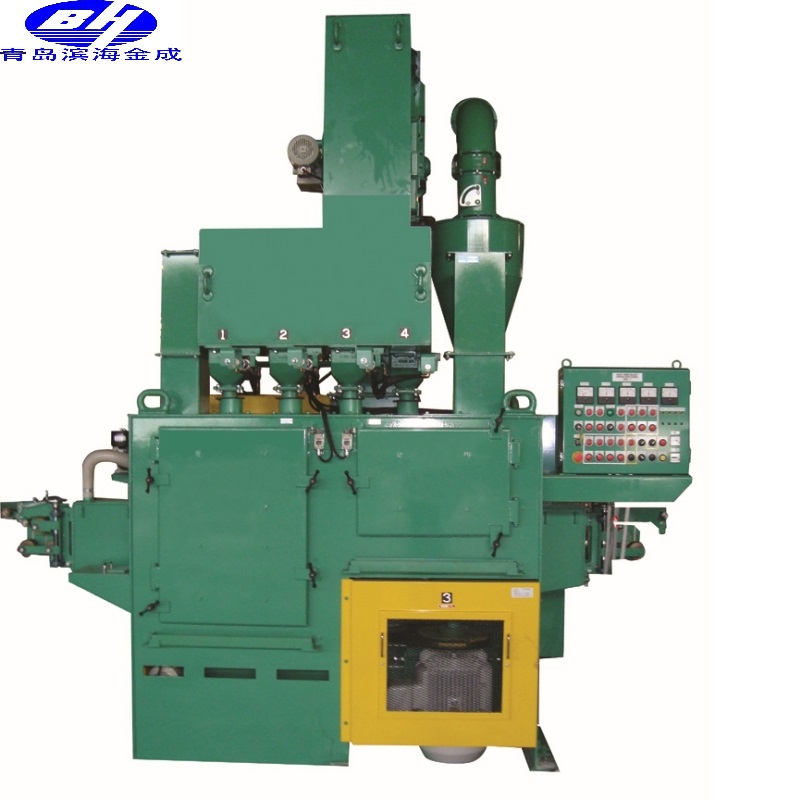

Umshini wokuqhumisa amapayipi ensimbi

Umshini wokuqhumisa amapayipi ensimbi

Umshini wokuqhumisa amapayipi ensimbi uwuhlobo olusha lwemishini ekhethekile yokudubula eyenzelwe izidingo zabasebenzisi, esetshenziselwa ngokukhethekile ukuhlanza udonga olungaphandle lwamapayipi amakhulu ayindilinga ensimbi nemibhoshongo yomoya yamandla omoya, futhi kwezinye izimo ukuhlanza izindawo ezingaphakathi nengaphandle. wamapayipi ensimbi.Ngokuqhunyiswa kokudubula, akugcini nje ukususa ukugqwala, isikali, i-welding slag, ukuphonsa isihlabathi ebusweni bomsebenzi, kodwa futhi kunganciphisa ukucindezeleka kwangaphakathi kwe-workpiece, ukuthuthukisa ukumelana nokukhathala kwe-workpiece, ukwenza ubuso be-workpiece. insimbi futhi ikhulise ingaphezulu le-workpiece Ukunamathela kwefilimu kapende ngesikhathi sokudweba kuthuthukisa ukusebenza kwe-anti-corrosion yepayipi yensimbi nensimbi eyindilinga futhi kwandisa impilo yesevisi yendawo yokusebenza.Futhi ekugcineni ufeze injongo yokuthuthukisa yonke indawo kanye nekhwalithi yangaphakathi yamapayipi.

| Idatha yobuchwepheshe | QGW20-50 | QGW80-150 | |

| Qoqa ububanzi beshubhu(mm) | 30-500 | 250-1500 | |

| Izinga lokugeleza kwe-abrasive(kg/min) | 2X260 | 2X260 | 2X750 |

| Isivinini sokuhlanza(m/mim) | 0.5-4 | 0.5-4 | 1-10 |

izici eziyinhloko Steel pipe shot blasting umshini

1. Umshini wokuqhumisa isibhamu usebenzisa ilungiselelo lokuqhumisa phezulu.Ngenxa yokuthi indawo engaphansi yepayipi yensimbi enobubanzi obuhlukene idluliswa etafuleni le-roller ngokuphakama okufanayo, i-blaster edubulayo idubula ukusuka phansi ukuya phezulu, futhi ibanga phakathi kwe-abrasive nengaphezulu lepayipi lensimbi liyafana, lokho ukuthi, umphumela wokuhlanza ufana kakhulu.

2. I-workpiece idlula ngokuqhubekayo endaweni yokungena nokuphuma komshini wokudubula.Ngenxa yokuhlanzwa kwepayipi lensimbi ngobubanzi obukhulu, ukuze kuvinjwe i-abrasive ukuthi ingandizi ngaphandle, umshini usebenzisa ibhulashi lokuvala elishintshwayo elinezingqimba eziningi ukuze kuzuzwe uphawu oluphelele ku-abrasive.

3. Ukusetshenziswa komshini wokuqhumisa we-centrifugal cantilever wenoveli osebenza kahle kakhulu onemisebenzi eminingi, inani elikhulu lokudubula, ukusebenza kahle okuphezulu, ukushintshwa kwe-blade ngokushesha, nokusebenza kokushintshwa sekukonke, ukulondolozwa okulula.

4. Umdwebo olingisayo oqhumisayo (okuhlanganisa nokunqunywa kwemodeli, inombolo kanye nokuhlelwa kwendawo yomshini oqhumayo) kanye nayo yonke imidwebo yomshini oqhumayo idwetshwa ngokuphelele umklamo osizwa yikhompyutha.Izinga lokusetshenziswa kanye nokukhiqizwa komsebenzi we-abrasive kuyathuthukiswa, umphumela wokuhlanza uyaqinisekiswa, futhi ukuguga kwepuleti lonogada legumbi kuyancishiswa.

4. Kusetshenziswa isihlukanisi se-slag esigcwele ikhethini le-BE-type, esithuthukisa kakhulu inani lokuhlukanisa, ukusebenza kahle kokuhlukanisa kanye nekhwalithi yokuqhuma kwesibhamu, futhi kunciphisa ukuguga kudivayisi yokudubula.

5. I-Rolling Mn13 steel plate isetshenziselwa ukuvikela ekamelweni lokuhlanza, futhi ipuleti yokuzivikela igxilwe yinati elikhethekile.Kulula futhi kulula ukuyifaka esikhundleni futhi inokuphila kwenkonzo ende.

6.Ukudlulisa umugqa wokuxhuma

Ulayini wokuxhumanisa wokudlulisa ungathola ukulawulwa kwesivinini esingenasinyathelo ngesiguquli sefrikhwensi.Ukuze kuqinisekiswe ukuthi lapho amapayipi ensimbi emininingwane ehlukahlukene edutshulwa ngesivinini esishiwo, ipayipi lensimbi linezikhathi ezanele zokushintsha ekamelweni eliqhumayo ukuze kutholwe umphumela ongcono kakhulu wokudubula.

Ukulungiswa kwesikhala se-roller kwenziwa idivayisi yokulungisa.Iqembu ngalinye le-roller lixhunywe induku yokuxhuma, ukuze ukulungiswa kokuvumelanisa kufinyelelwe.Indlela yokulungisa ingashintshwa ngokuya ngamadayimitha epayipi ahlukene ngokwezidingo zomsebenzisi.

Irola ngalinye lingazungeza phakathi nendawo kubakaki ukuze lilungise i-engeli yalo ukuya lapho lidlulisa khona.Uma ijubane le-roller lihlala njalo, isivinini sokudlulisa kanye nesivinini sokujikeleza kwe-workpiece siyashintshwa.I-engeli ye-roller ilungiswa ngokuhambisana ne-ratchet ne-pawl mechanism.

Amandla e-roller ngayinye akhiqizwa yi-reducer, futhi izinombolo ezihlukene zokunciphisa zingahlelwa ngokuvumelana nezidingo zamandla.Umbuthano wangaphandle we-roller uyirabha eqinile, enakho kokubili ukuqina nokumelana nokugqoka futhi ingasekela ngokuphumelelayo ipayipi yensimbi.

7, Ipayipi lensimbi ligcina lijikeleza.

8,Umqoqi wothuli usebenzisa isiqophi sokuvikela i-pulse filter cartridge blowback uthuli.Umqoqi wothuli unendawo enkulu yokuhlunga kanye nomphumela omuhle wokuhlunga.

9, Idizayini yomshini iyinoveli ekwakhiweni kwayo, kulula ukuyisebenzisa nokuyinakekela.

10,Usebenzisa idivayisi yokubona amaphutha ezenzakalelayo ukuze ubone umsebenzi we-alamu wokuvala shaqa okuzenzakalelayo.Lo mshini unezici zesakhiwo esithuthukisiwe, ukuklama okunengqondo, ukusebenza okuthembekile nokusebenza kahle kokukhiqiza okuphezulu.

11, Ngaphandle kwesakhiwo somgodi, ukugcinwa okulula.

Steel pipe shot shot blasting machine Izici zesakhiwo

1.ukuhlanza ukulandelana

Iyalayisha (kunikezwe umsebenzisi) → umugqa wokuxhumanisa → faka igumbi eliqhumayo → ukuqhuma kwesibhamu (i-workpiece iyazungeza ngenkathi iqhubeka) → phakela igumbi eliqhumayo → umugqa wokuxhuma → ukukhulula (kunikezwe umsebenzisi)

2.Abrasive Circulation Sequence

Isitoreji Esiqhumayo → Ukulawula Ukugeleza → Ucezu Lokusebenza Oluqhuma Isibhamu → Ikheshi Lebhakede Liphakame Lime mpo → Ukuhlukaniswa kwePellet → (Ukwenza kabusha)

4. Izici zesakhiwo

Isakhiwo somshini siqukethe itafula lokudla (amamitha angu-12), umshini oqhumayo, itafula lokudla (amamitha angu-12), uhlelo lokulawula umoya, uhlelo lokulawula ugesi kanye nohlelo lokususa uthuli.

Umshini oqhumayo wakhiwe i-shot blasting chamber, i-shot blaster assembly, i-shot hopper ne-grille, isihlukanisi se-shot slag, ikheshi, isitebhisi sesiteji, uhlelo lokuhlinzeka ngesibhamu nezinye izingxenye.