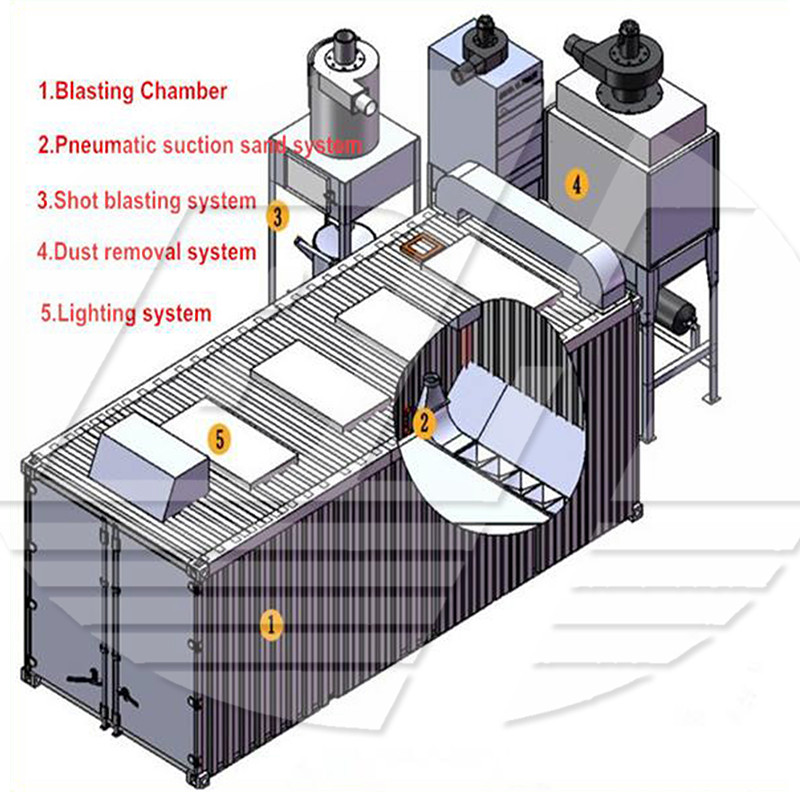

Umsebenzi womshini wokuqhumisa wohlobo lwe-catenary

Umsebenzi womshini wokuqhumisa wohlobo lwe-catenary

Q38,Q48,Q58 uchungechunge catenary stepping shot shot umshini osetshenziswa ukususa castings, forgings, izingxenye zesakhiwo ezifana workpiece surface isihlabathi, isikali, ukugqwala nokunye.Ingaphezulu workpiece ibonakala icwebezela metallic, futhi castings surface ukukhubazeka obala ukuze kuqedwe ukucindezeleka ngaphakathi workpiece, ubulukhuni ebusweni ukuze Ra12.5 izidingo GB6060.5, ngokuhambisana kazwelonke JB / T8355-96 Sa2.5 level.

Ukucaciswa kwemodeli eyinhloko yomshini wokuqhumisa wohlobo lwe-catenary

| Uhlobo | Ivolumu yokuhlanza isiqeshana sokusebenza(mm) | Izinga lokugeleza kwe-abrassive (kg/min) |

| Q383 | Φ 600 x 1400 | 4 x260 |

| Q384 | Φ 800 x 1500 | 6 x260 |

| Q385 | Φ 900 x 1400 | 4 x260 |

| Q4810 | Φ 1000 x 1500 | 6 x260 |

| ipharamitha | Q583 | Q585 | Q5810 | Q588 | |

| ubukhulu bomsebenzi wokuhlanza | mm | 800 x1500 | 800 x1200 | 1300 x2800 | 550 x2200 |

| inombolo hook | Setha | 2 | 4 | 6 | 4 |

| inombolo ye-blaster | kg | 4 | 6 | 6 | 4 |

| izinga lokugeleza kwe-abrasive | kg/min | 4 x250 | 6 x360 | 6 x330 | 4 x480 |

| amandla we-blaster | kw | 4 x15 | 6 x22 | 6 x22 | 4 x22 |

| max.weight of Crane loads | kg | 300 | 500 | 1000 | 800 |

| umthamo nge hook | h | 40 | 55 | 50 | 30 |

| ubukhulu bekamelo lokuhlanza | mm | 3062 x1800x2800 | 8500 x1800x3885 | 8500 x2300x4800 | 6800 x2600x3325 |

| umthamo womoya ophelele | m³/h | 15000 | 18000 | 18000 | 17200 |

| amandla aphelele | kw | 74.5 | 186.85 | 186.85 | 121.05 |

Isicelo somshini wokudubula wohlobo lwe-Catenary:

Hlanza Iron Casting

Hlanza Steel Casting

Hlanza Forging

Hlanza izingxenye zokunyathela

Hlanza isilinda se-LPG

Olunye uhlobo lwensimbi olusebenza kahle kakhulu lokuhlanza

Isici somshini wokudubula we-Catenary

Thuthukisa ukumelana nokukhathala kanye nokulwa nokukhathala

Susa isihlabathi sensimbi

Khulisa impilo yesevisi

Susa ukugqwala kwensimbi

Susa isikhumba se-metal surface oxide

Yenza ubuso bubonise ukucwebezela kwensimbi.

Thuthukisa amandla okunamathela ngaphambi kokudweba

Susa ingcindezi yangaphakathi

Izici Eziyinhloko

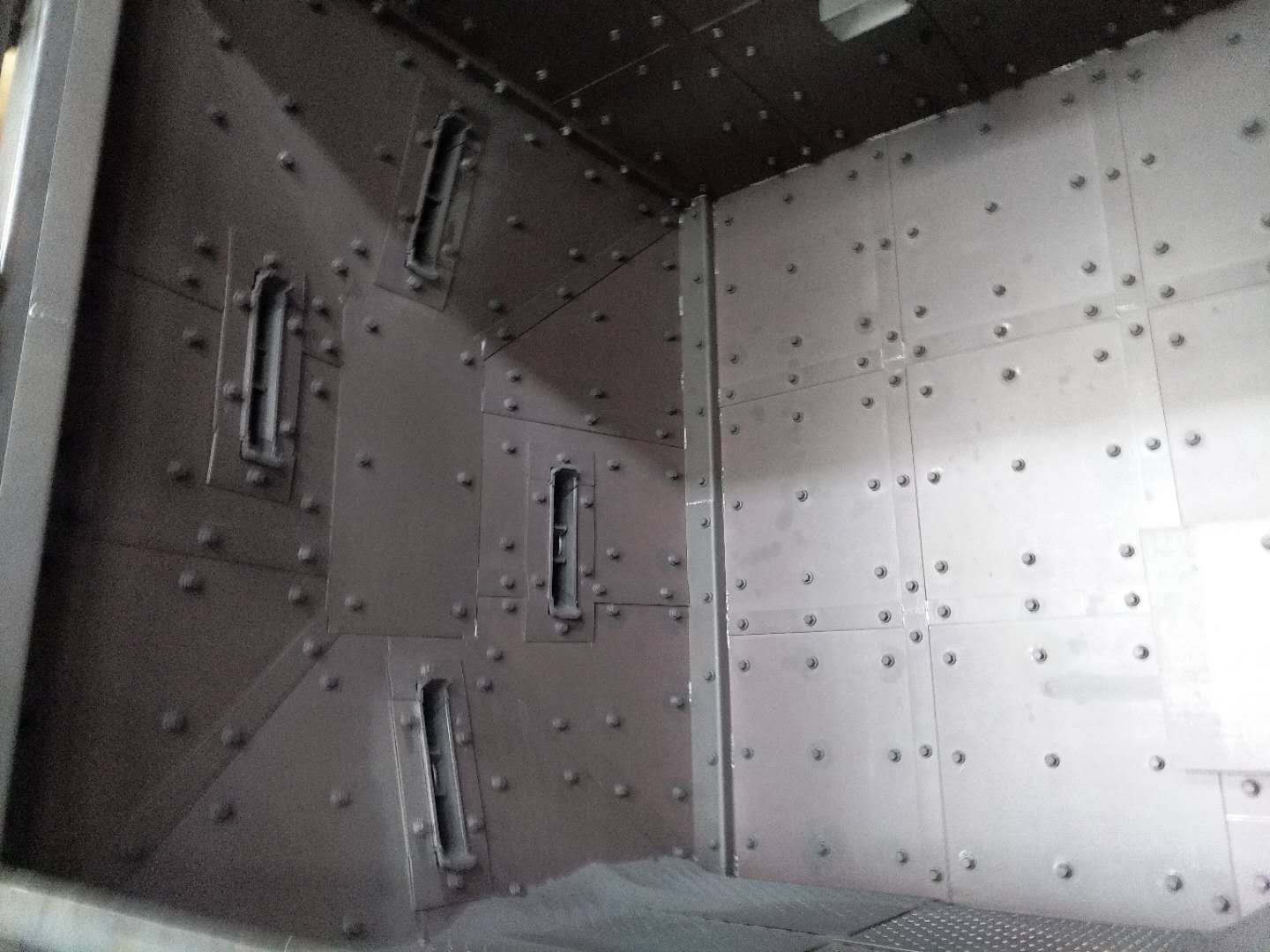

1) Ibhodi lokuvikela le-manganese 13, i-8000-10000 ihora lesikhathi eside sokuphila.

2) Isithumeli sethrekhi somumo oqondile noma ongu-Y, umthamo wokulayisha 500-50000kg

3) Ijubane eliphezulu lokuhlanza kanye nomsebenzi osindisayo.

4) izingxenye ezisele ze-turbine zonke ziyi-chrome ephezulu

5)isakhiwo esihlangene nesiqinile

6)uthuli lokuhlushwa ngaphansi kuka-80mg/m3

7)angasebenzisa i-ABB motor,SEW reducer,SKF bearing

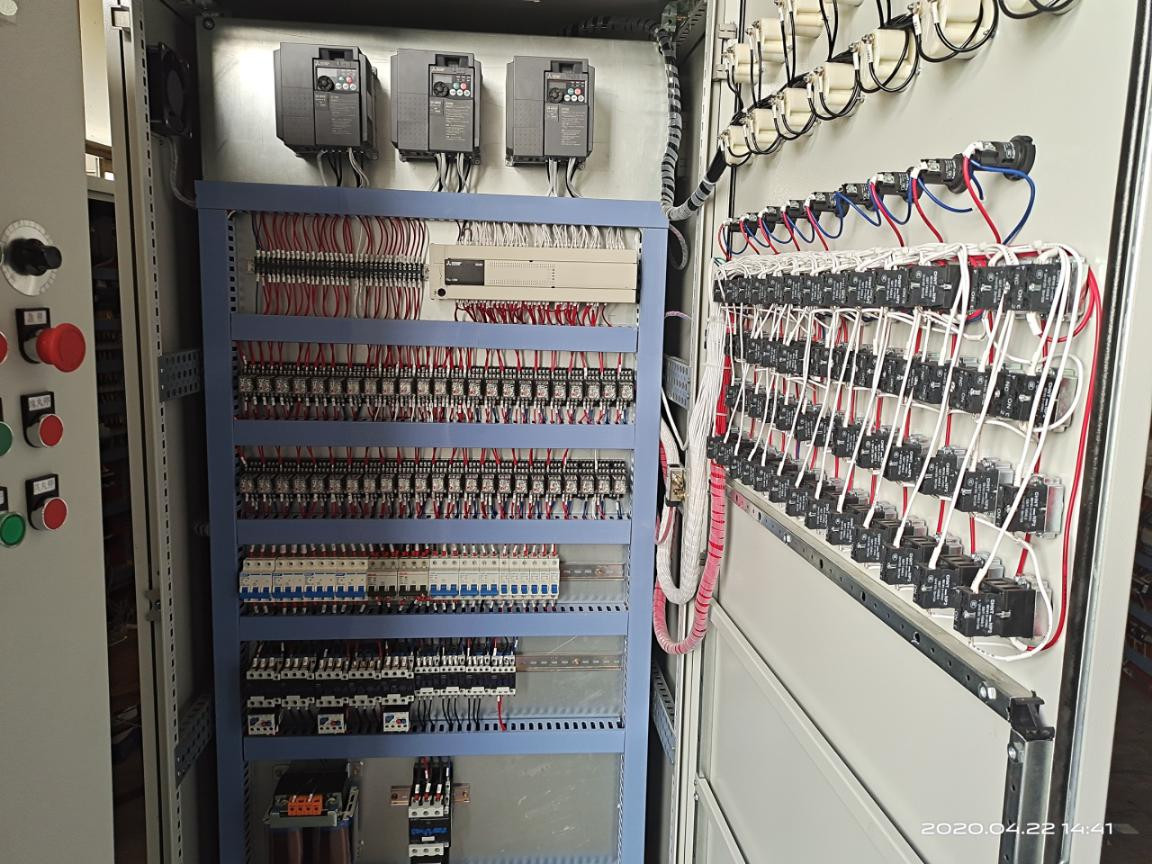

I-8) iphakheji: ibhokisi lezinkuni lekhabhinethi yokulawula

9)Isistimu yokulawula ye-PLC(Siemens noma i-Omron noma i-Mitsubishi), futhi ulungise ipharamitha nokuphepha

10)Isistimu yokujikeleza kwe-projectile isebenzisa idivayisi yokuqapha esebenzayo.Uma ezinye izingxenye zingasebenzi kahle noma zibambeke, izohlaba umkhosi futhi yazise izingxenye ezinephutha, ezilungele ukulungiswa okuhlosiwe.

I-11) Izinto zokusebenza zingahlanzwa ngenkathi uhamba, noma uhamba ngemva kokuhlanza, njll., ngesinyathelo esiphezulu sesinyathelo, ukunciphisa kakhulu ukuqina kwabasebenzi.

I-10) isikhathi sokudiliva: phakathi kwezinsuku ezi-5 zohlobo olujwayelekile, ezinye ngokuvamile ziyi-15-60 izinsuku zokusebenza

Yimaphi amadokhumenti esiwanikezayo?

1.Imanuwali yokufundisa ingesiShayina nesiNgisi.Iqukethe

Umdwebo we-Lay-out, Umdwebo we-Lay out uzonikezwa phakathi nenyanga eyodwa ngemuva kokuthi inkontileka isebenze.

Iziqondiso zokusebenza, ukugcinwa kanye nokugcoba

Izikimu zikagesi

Uhlu lwezingxenye ezisele ezinconyiwe ezinamanani

Ukubhalwa kwezingxenye ezijwayelekile

2.Isikweletu sokulayisha,uhlu lokukha,isitifiketi semvelaphi

I-3.Engineer ingaya endaweni yakho usizo ukuze ifakwe