Isitsha sokuqhunyiswa kwesihlabathi se-BHQ26 esinenani lezomnotho

isitsha sokuqhunyiswa kwesihlabathi

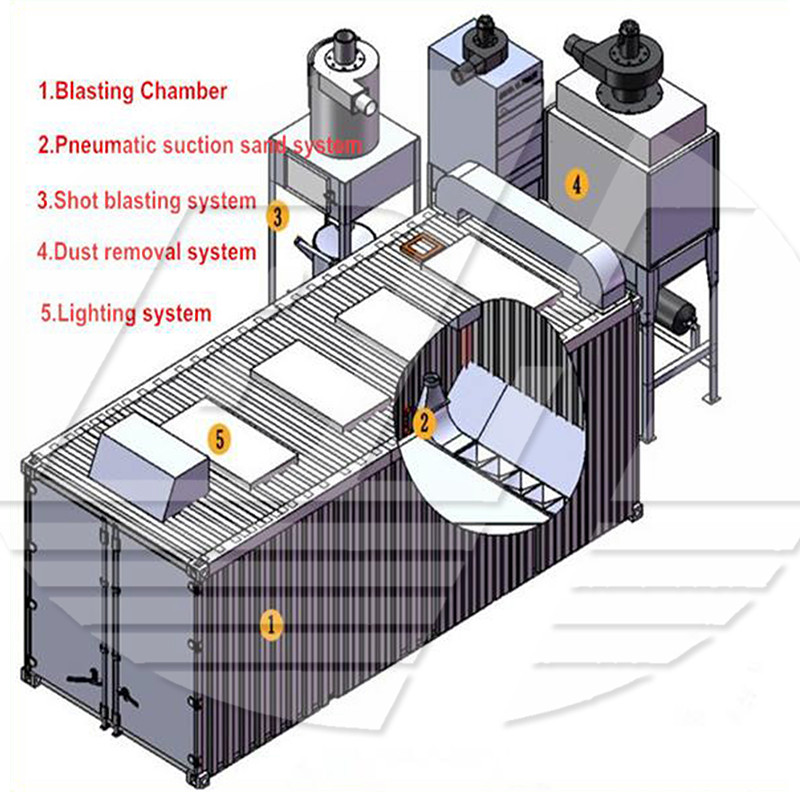

Ikakhulukazi yakhiwe i-shot Blaster assembly, i-shot blasting room, i-trolley transportation system, uhlelo lokususa uthuli, uhlelo lokulawula ugesi nezinye izingxenye.

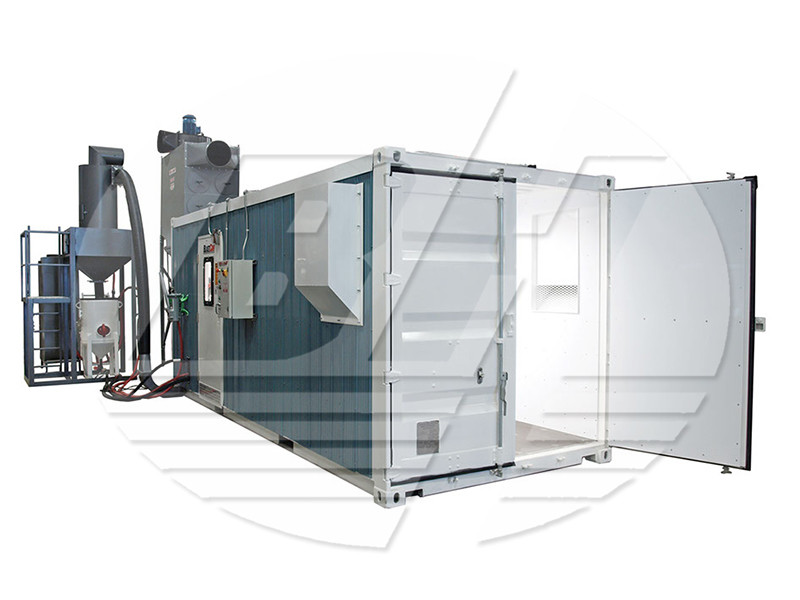

1 Igumbi lokudubula

Igobolondo legumbi lokuhlanza eliqhumayo lenziwe ngebhodi eliyinhlanganisela ye-steel iron rock wool composite kanye nesakhiwo se-rectangular steel welding riveting, okuyindawo eqinile, evalekile futhi evulekile yokuqhunyiswa kwesibhamu somsebenzi.Igumbi lokuhlanza eliqhumayo liqukethe izindonga ezingakwesokunxele nezingakwesokudla, udonga olungemuva, i-top plate, ipuleti lonogada berabha, kanye nesango.Igumbi eliqhumayo lifakwe izibani zensimbi ze-halide (ezivikelwe ngensimbi engagqwali).Ingaphakathi lekamelo livikelwe ngonogada benjoloba abamhlophe abangagqoki, futhi bonke onogada bafakwe amabhawodi obuhlalu.Umnyango wegumbi lokudubula usebenzisa i-folio yohlobo lwesitsha.

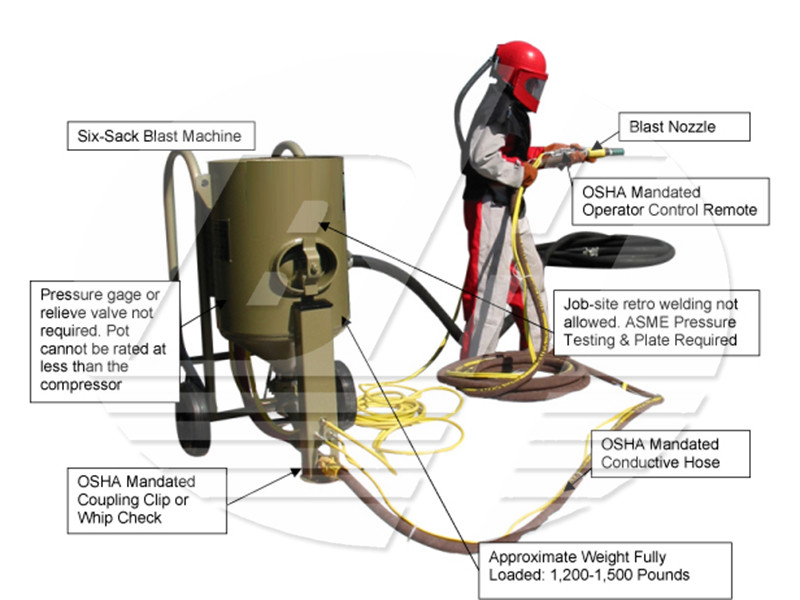

2 Umhlangano we-Shot Blaster

I-shot Blaster assembly yakhiwe ithangi, umlomo wombhobho, into yokuphefumula umoya, njll. Kuwumsebenzi omkhulu oqhubekayo wokuqhunyiswa kwesibhamu esiphindwe kabili.I-nozzle yenziwe nge-boron carbide futhi ihlala isikhathi eside.I-nozzle yenziwe nge-ultra-wearable high-pressure rubber tube Phakathi kwabo, ukukhiqizwa kwamathangi kuneziqu zokwenza imikhumbi yokucindezela.

3 Uhlelo lokuhlanza lokujikeleza kwephilisi

Idivayisi yokuhlanza ukujikeleza kwe-pellet ihlanganisa uhlelo lokujikeleza kanye nesistimu yokuhlanza ukuhlukaniswa kwe-pellet, eyakhiwe nge-screw conveyor, i-lifti yebhakede, isihlukanisi sesihlabathi se-pellet, i-valve yesango lokunikezela nge-pellet, kanye nepayipi yokulethwa kwe-pellet.

I-screw conveyor:

I-screw conveyor yenziwe nge-casing, i-screw shaft, i-bearing enesihlalo, indlela yokushayela, njll. Iyingxenye ye-serialized yenkampani yethu, enokuhlukahluka okuphezulu, ukushintshashintsha okuphezulu, nokusebenza okuzinzile nokuthembekile.

Le ngxenye inesibopho sokudlulisa ingxube yesihlabathi esidutshuliwe kwikheshi.I-screw conveyor itholakala ngaphansi kwegumbi lokuhlanza ukuqhuma okudutshulwa, futhi ama-screw blades ashiselwe ku-drive shaft.Lapho isebenza, i-conveyor motor ishayela i-screw conveyor ukuze ijikeleze ngesinciphisi se-cycloid ukuze ihambise ama-pellets endaweni yokukhipha amanzi, bese imbobo yokukhipha idlulisela ama-pellets ahlakazekile kanye nengxube yothuli phansi kwekheshi.

Iziphetho ezimbili ze-screw conveyor zivikelwe uphawu lwezinyathelo ezintathu, isembozo se-labyrinth seal yengezwa ngaphakathi kwepuleti lokugcina, uphawu lukawoyela lusetshenziselwa ukuvikela phakathi, futhi i-bearing ihlukaniswa nepuleti lokugcina ngaphandle kokuphela. ipuleti.Uma ama-pellets nothuli kukhishwa, bazowa kusukela ekhaleni phakathi kwepuleti yokugcina kanye ne-bearing futhi ngeke bangene ekuthwaleni.

I-lifti yebhakede:

Ikheshi lebhakede lakhiwe ngesinciphisi isivinini se-cycloidal pin wheel, amarola aphezulu naphansi, ibhande lokuthutha, i-hopper, umgqomo ovaliwe kanye nedivayisi yokucindezela, njll., kanye namandla adonsela phansi aphakathi nendawo asetshenziselwa ukuvala.

Lapho isebenza, i-hopper egxilwe ebhandeni lokuthutha ikhuhla ama-pellets phansi futhi ithumele ama-pellets phezulu, bese iwela ngamandla adonsela phansi amaphakathi.Ukwamukela ibhande lokudlulisela elikhethekile le-polyester wire core, amandla aphezulu nokusebenza okuphezulu okuqinile.

I-pulley ithatha isakhiwo se-squirrel-cage esine-protrusion encane phakathi, futhi ukukhuluma ngakunye kucutshungulwa nge-chamfering.Akugcini nje ukuthuthukisa ukungqubuzana phakathi kwe-tape yokuphakamisa kanye ne-pulley, igwema into eshelelayo ye-pulley yokukhanya yakudala kanye ne-pulley ebhande, kodwa futhi inciphisa ukuzenzisa kwebhande eliphakamisayo futhi yandise impilo yesevisi;ngesikhathi esifanayo, igwema ukushumeka kwebhomu ehlakazekile Phakathi kwe-pulley nebhande kuthinta ukudluliselwa.

Kukhona u-10% wemajini wokuphakamisa.Ngenxa yokuthi i-hoist iwela ngamandla adonsela phansi e-centrifugal, isikhathi ngasinye lapho uwa, kuyohlale kunengxenye yento ewela emuva endaweni ephakeme, ngakho-ke kuyadingeka ukwandisa inani lokuphakamisa ngokufanele.

Isihlukanisi se-Pellet:

Lo mshini wamukela isihlukanisi sezinsalela zephilisi lokugeleza kwekhethini eligcwele ikhethini elithuthuke kakhulu emhlabeni, futhi ukusebenza kahle kwalo kokuhlukanisa kungu-≥99.5%.Lesi sihlukanisi siwuhlobo lwakamuva lwesihlukanisi senkampani yethu.Isihlukanisi singenye yezingxenye ezibalulekile zale mishini.Usayizi wokuklama wendawo yokuhlukanisa uthinta ngokuqondile umphumela wokuhlukanisa wesihlukanisi.Uma umphumela wokuhlukanisa ungemuhle, uzosheshisa ukuguga kwe-blade yokuqhuma.

Isistimu yokuthutha ye-trolley engu-4

Ukuthuthwa kwezimoto eziyisicaba kuyamukelwa;ukuthwala umthwalo kwenziwa ngokwezifiso ngokwesimo sangempela sekhasimende.Ngokwesimo se-workpiece, phushela ngokwakho imoto eyisicaba egumbini lokuhlanza ukuze uthole ukuchama.Ngaphambili kwesondo kufakwe i-polyurethane scraper ukuze kukhishwe ama-projectiles ngaphezu kwesitimela.

5 Uhlelo lokususa uthuli

Isistimu yokususa uthuli ihlanganisa umqoqi wothuli we-cartridge, ifeni, imoto, ipayipi, ushimula, njll.

I-automatic pulse back-flushing, ivalve ekhipha uthuli isebenzisa ukulawula umoya, futhi umgqomo oqoqa uthuli onerola uhlelwa ngaphansi kwe-ash hopper, ukugwema into yesibili yothuli ebangelwa ukushaywa emuva.

I-cartridge yokuhlunga uthuli ingasuswa kalula ukuze ihlanzwe futhi isetshenziswe kabusha.

6 Uhlelo lukagesi

I-Shot blaster, umnyango wokulungisa, isilawuli se-projectile kanye nesistimu ye-projectile circulation konke kufakwe i-interlock kagesi kanye nendlela yokuzikhiya ukuze kuqinisekiswe ukusebenza okuthembekile kwemishini kanye nokuphepha kwabaqhubi.I-dust blower back blowing isebenzisa i-automatic pulse control.